Baseball

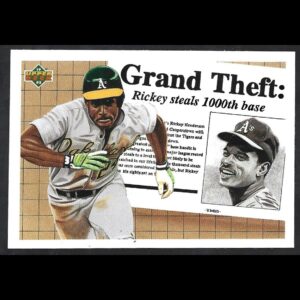

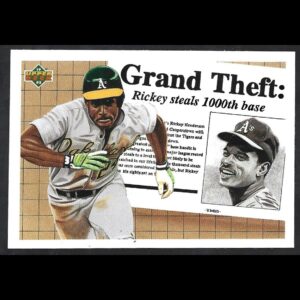

May 1, 1992 – Rickey Henderson Swipes His 1000th Base

Some records are made to never be broken. Rickey Henderson picked up his 1000th stolen base on May 1, 1992, exactly a year to the

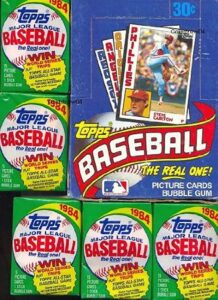

Baseball card wax packs were typically made using a process that involved several steps. Here is a general overview of how they were made:

Baseball card wax packs were typically made using a process that involved several steps. Here is a general overview of how they were made:

The process of making baseball card wax packs varied somewhat depending on the manufacturer and the era in which they were produced. However, the basic steps outlined above were common to most baseball card wax pack production processes.

Some records are made to never be broken. Rickey Henderson picked up his 1000th stolen base on May 1, 1992, exactly a year to the

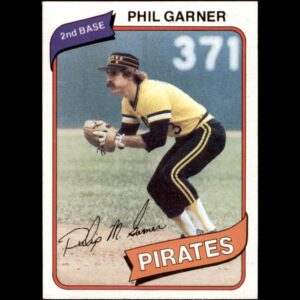

Today we salute Phil Garner, who turns 75. Despite a 16-year playing career from 1973 to 1988, we have no memory of his playing days –